To reduce vibration coming through the handlebars:

- thicker grips

- grip covers (like Grip Puppy)

- crash bars (adds rigidity and weight to frame

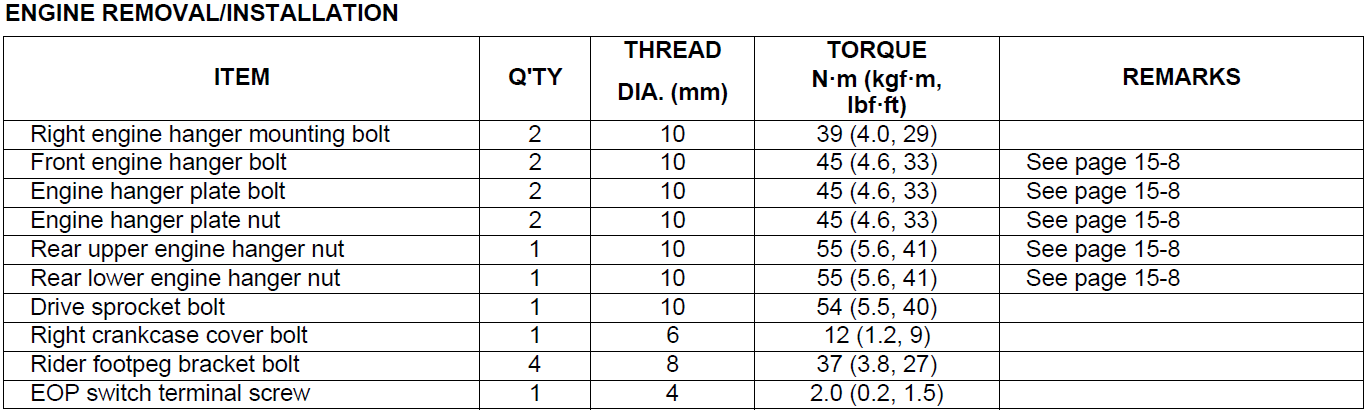

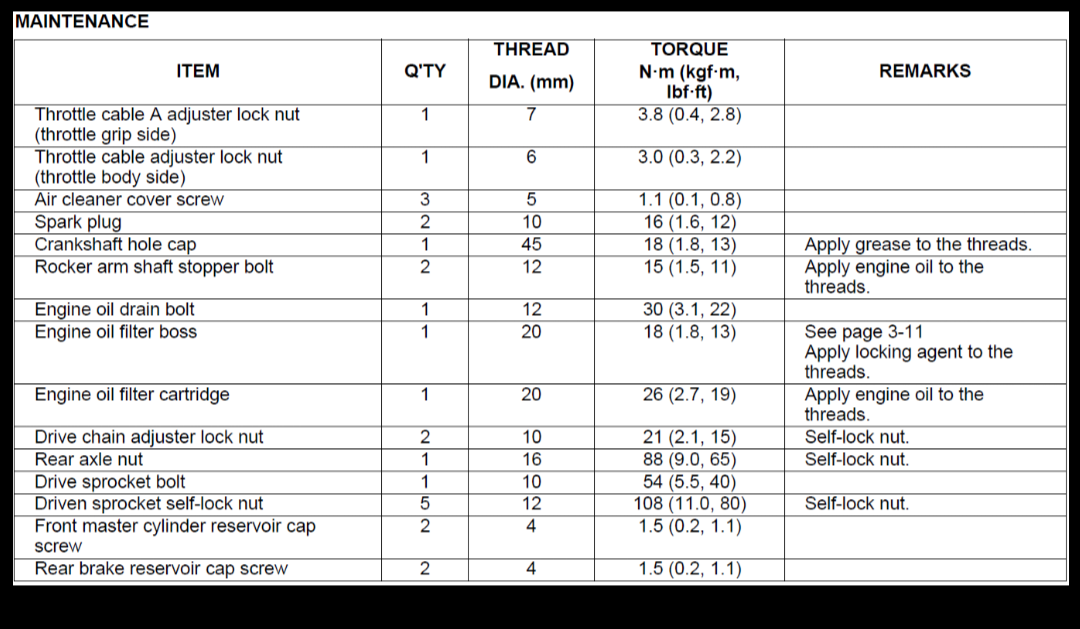

- tighten all motor mount bolts (torque settings are below)

- if you have removed the driver footpeg rubber inserts, put them back in for less vibration through the pegs.

- add nylon washers to the driver footpeg braces – you need four washers.

- rubber mounting for the bars

- anti-vibration motor mount bar – remove the two lower front motor mount bolts and replace with one 3/8″ threaded rod and buy frame sliders for the rod ends. {optional: Any weight you can add before the frame sliders go on will help. I experimented adding 3 lbs of weight and it made a noticable reduction in vibration. Walmart sells 1.25 lbs “CAP” Barbell weight plates for $1.88 each. You could use 1 or 2 per side. Threaded rod should be 14.5 to 16 inch long – put it in place with all weights and sliders BEFORE you cut it.}

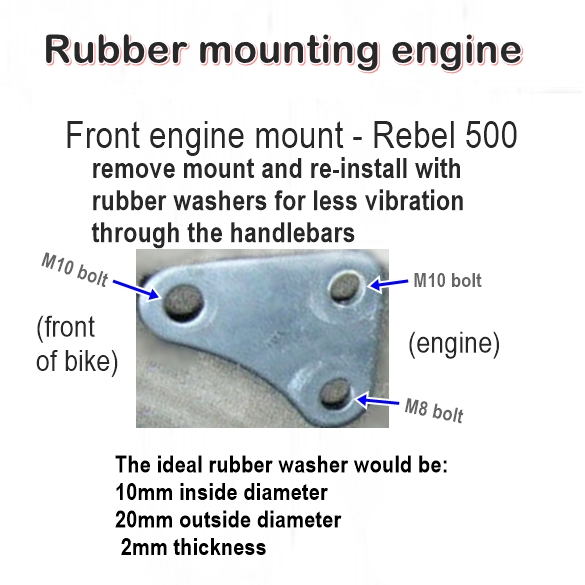

- add nylon washers to front motor mount

- (Rebel 300/500/1100 already has bar weights)

How to mount Rebel 500 crash bars on a Rebel 300 if you DON’T have the long lower bolt – remove the two lower front motor mount bolts and replace with one 3/8″ threaded rod from Home Depot (optional: buy frame sliders for the rod ends.) You need washers and nuts, also. Threaded rod should be 14.5 to 16 inch long – put it in place with all washers or sliders BEFORE you cut it. Use hacksaw to cut it.

——————–

Rubber mounting my Rebel 500 engine greatly reduced vibration coming through the handlebars. (My grips are stock and my gloves are 10 year old Joe Rocket gloves.)

Basically, you remove each front engine mount and reinstall it with neoprene or plastic washers.

There are two front engine mounts – left and right.

————————————–

Nylon washers

The second time I worked on this I changed to nylon washers. They do not absorb vibration as well but they are more durable and you can tighten them more. I bought 10mm x 20mm x 2mm black nylon washers on eBay – I got 50 for $2.49 USD plus $2.99 USD shipping.

Rubber washers

A regular rubber washer will not last long in this usage – a better choice would be neoprene or silicone.

The ideal rubber washer would be

10mm inside diameter ….. 20mm outside diameter … 2mm thickness

or 3/8″ inside diameter ….. 3/4 or 7/8″ outside diameter … 1/16″ thickness

I am buying these at Home Depot: 3/8 in. x 13/16 in. Black Neoprene Washer model # 815758 (3-Pack $1.18; need 4 packs) by Everbilt (1/16 or 1.6mm thick)

Here are some examples from Amazon:

—————

If possible , use a 25mm metal washer over each rubber washer.

Tighten bolts snugly; do not torque them down. Check tightness after the first few days. Use double nuts, wire, or some sort of retention for all nuts.

————————————–

Additionally – at the top of engine, I added rubber compressed to absorb vibration (there is no upper engine mount).